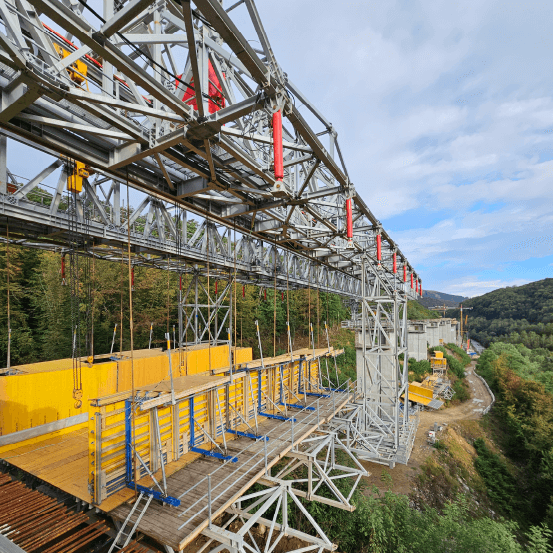

R2 Kriváň-Mýtna | 209-01

SLOVAKIA (MSS M1-70-S) 2021-...

Banksá Bystrica, Slovakia

2021-...

Type: Viaduct, total length 690 m (2263.78 ft)

Typical Span: 70 m

Deck width: 26,7 m (87.6 ft.)

Typical Cross Section: Box (Cast of the box in two phases: 1st U + 2nd upper slab)

Model: MSS M1-70-S

Construction Type: In situ (In Place)

Type: Overhead MSS

OPS System: N/A

Performance: 22-day cycles

• Construction method reliability and quality

• Large deck with complex geometry (polygonal geometry in plan)

• Fast construction capacity

• M1-70-S capable and already tested with success

• Deck load control during launching operation

• Formwork studied and adapted for this type of construction

• Formwork opening by rotation of transversal structures

• Deck extension using prefabricated slabs

• Adapted and optimised assembly process

• WORK IN PROGRESS